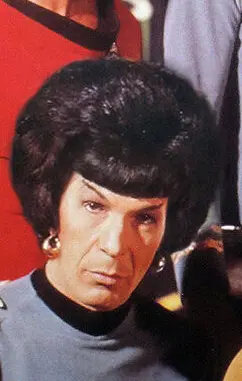

When an artificer and a rouge are faced with the same problem.

Edit: my english sucks

What does makeup have to do with this?

Rogue is not spelled rouge.

I think you replied to the wrong person. They know.

DM: Roll a D20 for a stealth check.

Rouge: I bat my eyelashes.

DM: Huh, I misread your character sheet. I’ll allow it.I feel like an artificer would be skilled in the application of rouge. As well as foundation and eyeliner.

*eyeliner

Still cheaper than getting a 3D printer and filament and stuff. And CAD/CAM software.

It’s true that you should not expect to save money in the short or long run with 3d printing as a hobby, but if it’s your thing then it’s nice to have a hobby that’s occasionally useful. Also, autodesk fusion is free for consumer use.

I wouldn’t say I’ve made back my investment on 3D printing in the past half a decade I’ve done it. But in terms of “prints for friends” like this one above I may be close. Plus there’s just something nice about going “I need a measuring cup for dog food” and printing one to the exact serving size.

What food-safe printing materials do you use?

I just use PLA. PLA itself is good safe, but occasionally the additives aren’t, so I don’t use any for human related stuff. It’s also worth considering that the layered approach can allow for bacterial growth, so unless you treat it (e.g. epoxy seal it), you’ll need to wash it fairly frequently to curb buildup.

That frequent washing is what leaks out the nasty chemicals from the plastic fyi. Heat and mechanical stress are the main way plastics leach

To be fair, that’s the case with pretty much all plastics.

Tupperware shouldn’t be used to reheat food in the microwave for the same reason, yet that’s it’s most common use generally.

Untreated PLA is more brittle than commercial food-safe plastics though, that is true.

Software is free if you aren’t using it for commercial use. Fusion 360, onshape, etc. are all free for personal use. And that’s assuming someone didn’t make it already and share it free.

Filament costs $17 for 1kg of perfectly fine plastic. You’d probably use 100g at most for this, so $1.70.

A Bambu A1 mini is $200, and is a modern, high quality printer that would be fine for this project.

So you only need like a half dozen of these projects to come out ahead.

On software SIDE, kinda criminal not to mention FreeCAD, it’s FOSS and runs on Linux, unlike the non-free freemium and paid alternatives

But it’s got a long way to go before it’s at usable as the others. Definitely not a good place to start learning cad.

No, it doesn’t.

The recent 1.0 release is actually very good. It is probably better at this point than some of the entry level commercial options and most importantly compared to those is not intentionally hobbled in any way.

The time for everyone to stop parroting how “everyone knows” that FreeCAD is unusable is… now. You can go ahead and delete that one; it’s time to learn a new soundbyte.

Come on. The 1.0 release is a huge milestone, but saying it’s better than the entry level commercial options is just disingenuous.

I have actually switched over to it because I run a small 3D printing business as a side income, which isn’t nearly profitable enough to afford an onshape license, and although Fusion360 has an affordable startup license it simply won’t work on Linux and my hackintosh laptop isn’t powerful enough for cad.

It is at a point where it is very usable if you are willing to invest the time needed to learn it, but the learning curve is much, much steeper than that of OnShape or Fusion360, especially if it is your first CAD program. There is also a huge lack of beginner tutorials for it, and the documentation is intended for advanced users, which complicates the learning curve even further, because Fusion360 and OnShape have a huge amount of beginner tutorials for them.

For a hobbyist that just wants to model a few things and not sell them I would always recommend OnShape or Fusion360 over FreeCAD, or even Tinkercad if said person just wants to model extremely simple things.

Is it much different from 7 months ago?

Yes. The 1.0 release was in November. That Ondsel fork in your video was based on, I believe, the 0.22 version.

The 1.0 release actually prompted Ondsel to shut down entirely, as they are now largely redundant and attempting to monetize a FOSS program was probably doomed from the start anyway…

That’s good to know, I guess I’ll give it a try again.

Nah it’s a great place to start learning, it’s super easy to start modelling your first simple models in part design.

It’s the more complex designs where it starts to struggle (or maybe I’m just bad idk)

Nah it’s not you, FreeCAD is perfectly usable for something like the above referenced knob but even mid-size assemblies really have problems. I personally find the workflow to be bad and irritating beyond my ability to express in words and I can’t imagine how frustrating it would be as a new user to work it out for yourself while at the same time getting used to thinking of objects as collections of operations. It’s a great lightweight program for people who already know what they’re doing and that value FOSS, though. 1.0 really fixed a ton of the issues, but it still has the “Blender UX” problem that seems to plague all big FOSS projects…

To be clear, I’m the last one to say one shouldn’t invest in money saving innovation. But the breaking even should be number one priority. I, for instance have all kinds of energy savers in my house that have cost me several hundreds. They’ll only be returned in a few years and I need to manage them properly.

One doesn’t buy a 3D printer to make a knob. One is suddenly presented with a need for a knob (or a thingy, or a flangle, or a twizzlet…) and suddenly remembers, “hey - I have a 3D printer.” Followed by “I wonder if there are any matching designs in one of the several massive free databases of models.”

Followed by getting out the calipers and opening OpenSCAD

The type of person to do this most likely already has a 3d printer, and cad software is free for personal use. The electricity and filament cost for this part would be a few cents and it would take minutes to print on modern printers

Even if you didn’t have a 3d printer it would be significantly cheaper to use a 3d printing service to order the part, than to buy OEM replacement knob

Also a high probability they have a 3D printer and are super excited for something useful to do with it.

If you do not have a 3D printer and CAD software, you are 100% right.

If you already have those things like OP, then why not just design / print one? I am also a 3D printer / CAD person, and I love designing replacement parts that are wither too expensive, or often impossible to find. Mostly though, I design and print things that make my and my families lives easier / nicer / more convenient. And they are customized to the exact item and function, something that you would most likely never be able to get in a store or online.

Stove Knob guards. https://www.printables.com/model/278668-stove-knob-guard

Salt / Pepper Grinder Holder. https://www.printables.com/model/155219-salt-and-pepper-grinder-caddy

Spice Jar Organizer. https://www.printables.com/model/151171-spice-jar-spacer-organizer

Just to name a few things.

I simply pulled the knob off in the store & shoved the rest of the stove up my butt, later at home I printed the missing knob. It’s a simple life-hack, basically everyone is doing it.

Is this why your meatloaf always smells funky?

Me too I enjoy putting my meatloaf in Evil_Shruberry oven

It brings all the funky people to the yard tho

Wes Watson over here.

I hate that as a society it is somehow ok to steal for your convenience. Its the same thing with lots of other things as well. Don’t you just love it when you buy a product only to get home and find half of it was stolen?

A while back I would use those local secondhand auctions that mostly dealt in amazon returns. (As opposed to directly buying from amazon.)

I’m surprised how everything would be intact for a lot of items, but most commonly if I got bamboozled, it was something like, everything is fine except for missing a set of screws, or a single crucial knob or something.

People literally will just order the same thing again, pull the part they missed, and instantly return it. Which is especially scummy when it’s no longer a secret these returns just get destroyed or incinerated for no reason.

It’s just disgusting consumer-brain behavior. (Amazon, of course, being sheer evil, enjoys the market advantage of a “no questions” return policy.)

If it was a very specialty piece beyond a simple hardware store run, a lot of times I’ve been lucky enough to politely contact the manufacturer of a thing, sometimes I tell them I got it as a gift so they don’t ask for a proof of purchase. And they’ll just send me the missing bit. Free. Super simple. The most I had to do was take a picture of the model tag.

The fact that this was too much for people to bother with grosses me out.

Not to say this behavior is okay, but there are some companies that also just exploit the alternative to high heaven, like the post shows. You can pay $20 for a 12 cent replacement part, or order one and return it. Some people will pay for the part, but significantly less will when it costs and arm and a leg for something so cheap.

If Amazon was a legit normal business this wouldn’t have worked and everything would have been processed. As you said, sheer evil

mademakes this.I really appreciate that ikea instead has no questions asked small hardware replacement. Had a bed in my storage unit for years waiting for summers to kill the old landlord’s “pets”. Unfortunately in that time some important bolts rusted. Made me not need to throw the whole thing out

You mean like US healthcare insurance?

YOU WOULDN’T STEAL A BOSCH OVEN KNOB

Now you can

DON’T TELL ME WHAT I WOULDN’T STEAL

My oven is so old I came across an identical one in an e-waste pile behind a store. I stole the timer knob and mechanism so I don’t need to keep using the broken one (manual only) anymore.

You didn’t steal it, you 💫recycled💫.

*Reused, which is preferred to recycling even if the materials are 100% recyclable.

That’s what I told to the store employee I encountered coming to work via the back door. He wasn’t too happy but ultimately let me do it.

Imaging being mad someone is taking your trash.

Imagine getting mad someone is taking your employer’s trash.

I’d eyeball the measurements in Blender and laugh at my crooked knob every time I use the stove.

I laugh at my crooked knob all the time.

Removed by mod

That’s at least better than his wife. She laughs and points.

You’re still putting too much work into this. Just heat up the metal shaft where the knob was with a torch and press any old hunk of thermo plastic onto it. Now you have janky done even more quick and cheap.

What about the old vice grips that are now a permanent part of the stove trick?

Nothing is more permanent than a temporary fix.

Man, all the sinks I’ve seen over the years with vice grip knobs haha.

That’s a humongous oven, must be a 10+ person household.

Or its the house people designated as the holiday house, maybe! Only actually used fully a few times a year.

That’s my house. We have dual ovens and use them simultaneously several times a year, mostly holidays.

90cm.

We have one for our 4 adult, 2 kid household. Its amazing how often it’s not big enough for all sorts of things.

I think 2 X 60cm ovens make more sense in hindsight and they also dont take as long to heat up

I ended up with 8 hobs, 2 ovens, a grill, and a drawer on mine. It was there when I moved in, and I kept it. Damn thing is built like a tank.

I’ve never had to use more than 2 of the hobs at once.

I use one of the ovens for storing rarely used pans and things.

That sounds like the 48" Miele. If so, hang on to it. That son of a bitch currently retails for $17,599.

No, that is not a typo.

Not as fancy as that unfortunately.

It’s 100cm across and the branding has long since worn away. I think it used to say Panache on it at one point, but I can’t find anything about that brand online. Following a trail of spares that look like the stuff on it, it was possibly made by Newhome.

I’d take a picture but I’ve not cleaned it in ages so it looks like something out of a crack den.

And yet it runs with gas, as if we’re still cavemen cooking meat over open fires.

Its the cheapest ¯\_(ツ) _/¯

China mastered copying things well. A five pack of replacement knobs that actually match is $34 on Amazon. A crappy homemade knob for a $4000+ range is crazy.

China has also mastered modern slave labor. That someone makes thier own replacement instead of ordering some small uncomplicated part from across the globe isn’t crazy, it’s self-reliant and smart.

But that’s, like, just my opinion man.

I’m sure the prison firefighters out in California are real mad about China mastering modern slave labor

Oh I would go for the OEM part ten times out of ten, especially for such a nice appliance. Instead this person opted to make some plastic waste that will eventually be in the Ocean after we are all long dead.

Completely agree that Amazon garbage is terrible for humanity

I definitely agree that less plastic = better in general. But if you’re going to 3d print stuff, at least this is functional.

And I’m not here to argue. God it is nice to have a civil discussions on social media.

Sorry if I came off as argumentative. That certainly wasn’t my intent.

I was just trying to make the point that this person spent a lot of time and effort to do something subpar with plastic.

You didn’t seem argumentative to me at all. I’m genuinely happy to disagree about something and:

-just have it be civil

-no one takes it personally

-we find things we can agree on

I have a hunch that those knobs are just a thin sheet of metal wrapped around a piece of plastic, which would explain why one of the knobs broke off in the first place.

I could be wrong, just a hunch.

The knobs are “brushed stainless” plated plastic with plastic parts inside. It’s possible Bosch is using higher quality materials, but this is the standard Bosch range knob that goes on all of their ranges, so I suspect it’s made down to a price. They’re injection molded parts that cost about a quarter a piece including parts and labor.

The important parts of the knob are all inside the range. But still can cost as little as about 10 bucks for an OEM part and 15 minutes of repair work if one of those should break.

Makes enough sense. My point was that either printing a replacement or getting the OEM part will use about the same amount of plastic, assuming the printing only takes one attempt.

deleted by creator

And Bosch makes and generally stands by their good products. Yeah they’re a company, but they’re not the worst!

Also, where did original knob go, I need to know.

Some things are better left unknown.

It goes farther than that! The 34$ 5 pack is only that price because its already here in america to be shipped in a day or two. It came from china, where you can order the same thing for 1-5% of the price if you are willing to wait a month to receive it.

I was gonna bitch about it too but the cheaper Bosch ranges use the same knobs. It’s an off the shelf part that Bosch is charging a ridiculous premium for.

I wish I had pockets big enough to replace the flimsy Bosch drawers in my fridge that start to shatter as soon as you pull just a tiny bit harder than normal.

There are 3d models for some fridge drawers. I have a Frigidaire with similarly flimsy drawers and found a model for them.

How much did the printer and materials cost? Or the time to educate on cad and printing?

Just saying, it was likely far more money and time/effort than merely 12 cents.

If you didn’t learn it only for this project, that cost is already sunk regardless.

Either way the post itself contains the answer for those who haven’t already sunk that cost.

Also, aren’t ovens hot? Won’t a 3d printed part melt straight away, or is there some special material?

I don’t think knobs get very hot

Well crap. Here I was hoping my knob would get hot.

Depends on the material. ABS would be a decent material for this application - as long as you have a decent enough setup to scrub / clean the air in the chamber / room.

PLA would have a hard time in that position, PETG might be OK, Nylon may creep after too many heat cycles. Depending on how hot those parts get this is.

There’s a third, where the first person puts on thingiverse and we do it for fun without owning the actual unit

But what the hell happened to the other knob? I’ve done a lot of stupid shit around the stove but I can’t imagine what could happen to it.

Kids are a force

Wait you have kids and still sink money into crypto shillcoins? 😬

We wanted to fight corporate bailouts too, and it worked out well enough that we could afford to have kids.

From experience, we tend to use the same two burners, and one particular one, the most, by far. (Front left for us) After 15 years, the plastic on the underside of the original knob got worn and loose and almost broke. We rotated the burner knobs. The oven knob is doing the same thing, but it’ll need to be replaced or repaired. Like someone else said, they aren’t usually all metal construction, there’s plastic on the inside.

Channel locks, adjustable wrench, or plyers are also acceptable. Plus then ya know damned well where they are.

This is why I always buy cheap vice grips whenever I see them in a box of tools at an estate sale or something.

“Oops, I broke a handle on (thing).”

Clamps vice grips on the bit left over

“Fixed it.”

Right now both of the seats in my truck just have a vice grips for the reclining lever.

I had my shower knobs as vice grips for a long while

Wouldn’t that be susceptible to melting due to oven temps? Or is that probably made from a higher temp filament?

What’s the melting point of the regular filament? You’re supposed to touch the oven knobs it so it’s probably not much higher than 50 degrees.

50 degrees? How do your oven knobs even get that hot? Mine don’t change temperature at all, always room temperature. If your oven knobs get recognizably warmer (yet to spend of 50°) something seems to be awfully wrong with your oven!

They should not be that warm but it’s about the limit of what is comfortable to touch.

The comfortable temperature limit to touch is room temperature because anything higher indicates a broken oven which makes me highly uncomfortable.

50° K?

Hopefully if it’s a decent oven there isn’t that much heat on the outside. I guess if you just left the door open, it might eventually melt

Not really. You can print it out of ABS easily enough if that’s a concern, given that there is a good chance that is what the knob on any given residential range or oven is likely to have been made out of by the factory anyway.

As a matter of fact, since this is directly in my wheelhouse (not that wheelhouse, the other one) vis-a-vis both 3D printing and whitegoods, let’s take a look.

Being in the unique position to be able to do so, I grabbed a knob off of a random smattering of ranges. Here’s what I found from the ones that didn’t require taking them apart further to find the markings or scraping at them with a knife or something (hey, there’s the other wheelhouse):

- Maytag (Whirlpool): Stamped “ABS” on the inside.

- Bosch “Industrial Style” (similar to OP’s): PBT

- Whirlpool: PET

- Verona: ABS

- GE Base Line: ABS

PBT has a pretty similar melting point to ABS at ~235° C. With ABS it’s complicated, but I print ABS at 260° C for what it’s worth. PET is also typically given around 260-270. So these are all pretty similar to each other.

TL;DR: You should be fine with ABS.

Oh sweet, knowing how to use a knife is right up my wheelhouse too!

Glass transition temp of PLA is around 55-60C - that’s when it starts to get malleable. I’d be pretty surprised if the oven knobs get that hot.

Depends on the type of filament used and temperatures that are actually present at the knob. I would say no since the temperature required to melt (or warp) the knob would have to be high enough to cause some pretty severe burns if you touched it with your hand. if the knobs on the oven/range are getting that hot, there is a lot more to worry about here than the knob melting.